Always Ready to Help

AccroSeal® provides quality custom machined parts and top-of-the-line grease products whenever needed.

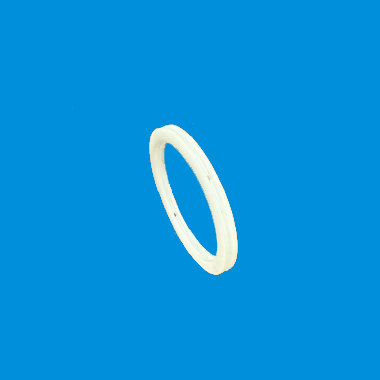

A Lantern Ring is a precision-engineered, perforated hollow ring placed within a stuffing box, typically between the packing rings of a pump or other rotating equipment. It plays a vital role in improving seal performance, extending equipment life, and maintaining efficient system operation.

The primary purpose of a lantern ring is to provide a controlled channel for introducing fluid—such as clean water, steam, air, or inert gas—into the stuffing box. This flush fluid is directed through the lantern ring’s perforations to cool, lubricate, and clean the packing material surrounding the shaft.

By doing so, the lantern ring:

Lantern rings are generally positioned between the middle packing rings—for example, between the third and fourth ring—in a multi-ring packing arrangement. This strategic placement ensures that the flush fluid reaches the heart of the stuffing box where it’s needed most.

Lantern rings are widely used in:

Lantern rings are available in a range of materials to meet varying service conditions: