Always Ready to Help

AccroSeal® provides quality custom machined parts and top-of-the-line grease products whenever needed.

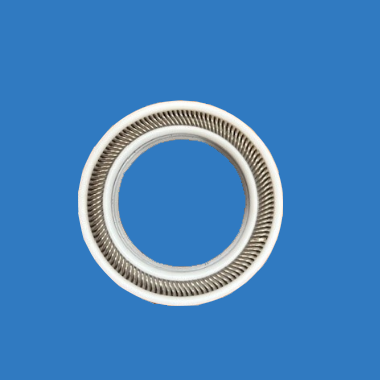

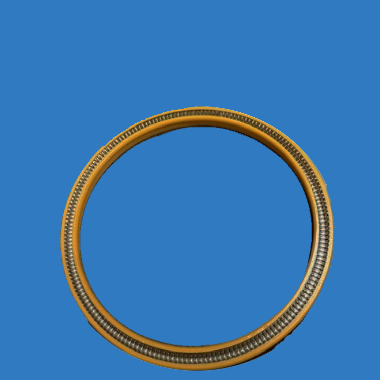

Spring-energized seals are precision-engineered sealing solutions designed for high-performance applications where standard elastomer seals may fall short. These seals combine the durability of high-performance polymers with the resilience of a metal spring to deliver consistent sealing force—even under extreme conditions.

At the core of every spring-energized seal is a metal spring housed within a polymer jacket. The spring applies a continuous radial or axial load to the seal lip, ensuring contact with the mating surface. This design allows the seal to adapt to fluctuations in pressure, temperature, and hardware tolerances, maintaining an effective seal even in challenging environments.

Each spring type offers distinct benefits, depending on the sealing requirements:

Spring-energized seals are a go-to choice when reliability, performance, and longevity are non-negotiable. Whether you're working in extreme environments or precision applications, these seals offer a proven, customizable solution.